Getting Prepped for a Harsh Winter: Winterizing and Preparing Farm Equipment

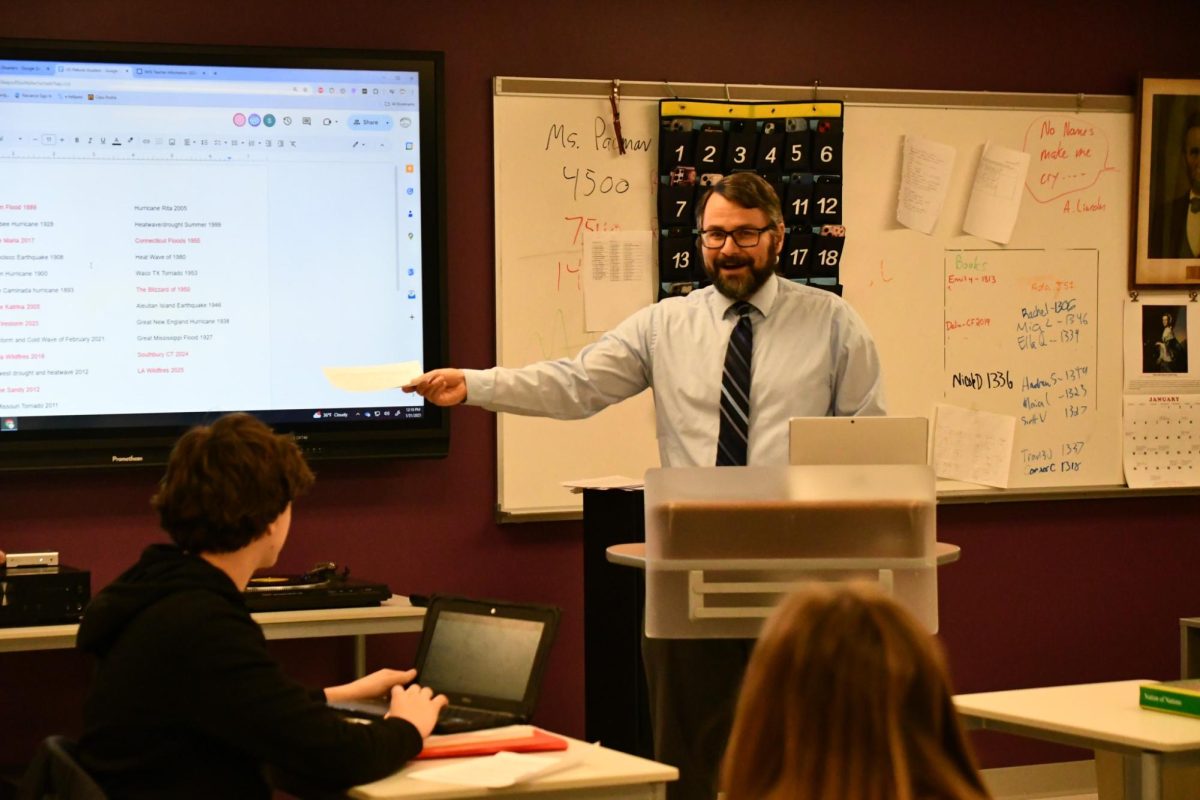

All NHS mechanics students are preparing campus farm equipment for the harsh winter weather to come.

December 17, 2021

WOODBURY — Farmers all over the world are getting their farming equipment ready for winter. Many farmers have different beliefs on how to store their equipment. How have farmers been storing their equipment over the last couple of years?

When a farmer is done growing and picking crops at the end of each year, they will need a cool, dry place to store their equipment from the harsh winter weather.

Many farmers choose a big barn or a garage. When it comes time, all farmers will pull out a grease gun to lubricate machine fittings. A grease gun is an electric battery gun that pumps out grease from a hose.

This task can be difficult due to accessing hard to reach fittings.

“Greasing is like finding a needle in a haystack, the fittings are all over the machine,” said Lenny Assard, a third-generation farmer.

To find all necessary grease fittings, the mechanic must view the whole machine, or many times refer to the parts manual. Once they know where all of them are located, they now must go one by one with the grease gun and pump grease into each individual fitting. This is to ensure the inner grease is clean and not clogged up.

Once all the fittings are clean and pumped full with new grease, the machine is complete unless it has a PTO (power takeoff) that must come off and be stored by a holder on the machine.

Once all the inner work and inspections are done, the farmers then start work on outside of the machine, if needed. They look for tire pressure, dents, and if the machine has blades, checking those is important. Checking for cracked hoses is also important.

When it comes time to put equipment away, most farmers have a specific way they like their equipment stored. For example, some farmers like to store their equipment in a certain order, such as from biggest to smallest so to minimize taking up unnecessary space. This process helps expand more work space and provides additional room for more equipment as the farm grows.

Once all the equipment is finally put away, in an orderly fashion, you are finished. Some farmers like to go a little farther though; they grease the tractors and get ready for plowing. They put large chains with springs that connect to the outer tire to the inner rim for more tread. This helps prevent sliding in snow. A lot of farmers like to add liquid calcium to the tractor tires for weight, and for better traction too.